This technological progress involves the use of adhesive materials that are:

- no longer sensitive to pressure;

- reduction of flammability;

- improvement of electrical insulation.

This ever-growing sector offers enormous prospects to all those who convert these high-performance materials.

Guidolin Girotto is specialized in the converting of all these new materials and with its team can support converters to face new converting challenges.

What are the criteria for battery components in temperature management

With the increase in popularity of electric vehicles, the challenge of temperature management also increases (in fact, hot batteries can slow down charging to the point of causing thermal runaway reactions) this is why battery components require specific criteria and standards.

Acrylic or silicone adhesives with retardant or flame extinguishing properties meet flame retardant specifications to ensure the highest industry standards.

The single- and double-coated components incorporate dielectric films that ensure high performance with regards to breakdown voltage and dielectric strength requirements.

Among the materials used in the construction of batteries we find mica. Durable and flexible, it has high thermal insulation properties therefore throughout the sector this material is used single or laminated as a non-combustible barrier. Also electrically insulates batteries and other important components.

How Guidolin Girotto die-cutting machines support converters

Guidolin Girotto die-cutting lines are ideal for converting these special materials necessary and suitable:

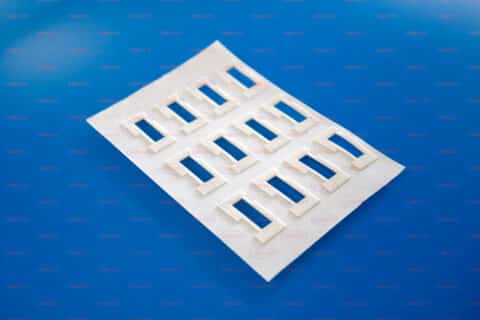

- in cell-to-cell bonding;

- in thermal runaway protection

- in package gasketing and electrical insulation of cells

Guidolin Girotto and its die-cutting machines guarantee excellent performance and very high cutting quality to support converters approaching this innovative sector, creating the clean cuts necessary for this type of product.